Research shows that our brains are so good at processing visual information that the brain can make sense of even briefly presented images.1 In fact, human beings have an inherent aptitude to use visual data to discover trends, identify anomalies, and process concepts.2

It makes sense, then, in this technological age that data visualization is not only an emerging trend but also an imperative. In this post, our fourth in the MSA FieldServer series about third-party integration, we’ll be talking about data visualization. More importantly, we’ll talk about why seeing data in graphical format makes it easier to process information, which leads to better decision making for your smart and automated buildings and facilities.

WHY DATA VISUALIZATION MATTERS

Like information shared through dialogue, data is only good if it can be synthesized, integrated, interpreted, understood, and disseminated. Fortunately, technology is enabling just about every industry to translate complex data sets. Visual data provides discoverable insights that let you accomplish a wide array of tasks and goals in ways that are timelier and more accurate.

A smart building manager has dozens, if not hundreds, of touchpoints each day to keep systems operating as they should. In the old days, people would need to be dispatched to read meters, check temperatures, monitor pressures, and the like.

Today, however, data visualization enables these checks to be performed remotely – and with fewer resources. More importantly, it results in what we like to call “quick and conscientious decision making.”

DATA SOURCES: THE GOOD, THE BAD & THE ESSENTIAL

Within supervisory control and data acquisition (SCADA) systems, there are literally hundreds of bits of data available relative to monitoring and controlling field devices at local and remote sites.

Here’s a look at data sources from a three-pronged perspective: the good, the bad, and the essential.

The Good: Data is only as good as its source. Your devices have plenty of good data; however, without some way to extract and translate it, it’s essentially locked inside the machine.

The Bad: If data is available but doesn’t make sense or isn’t quick and easy to understand the unfortunate fact is that it won’t be very useful. Unlocked but confusing or unclear data is an opportunity lost for important decision making.

The Essential: Essential data relies on relevant data presented in a way that makes sense and, for most of us, that means visually. Visual data presents a clear story that highlights critical information, ranging from exact numbers to comparisons and percentages to trends over time.

DATA TYPES, RETRIEVAL & TRANSLATION

Automation systems have numerous sources of data essentially floating around inside just waiting to be seen. Through a profile that we set for our customers, MSA FieldServer retrieves specific datasets from the machines that are connected to it. A subset of that data is then published to the system where it can be seen locally by authorized users. The data – or a subset of it – also can also be published to the cloud for globally remote access by authorized users.

The average automation systems manager looks at somewhere between 70 and 100 bits of data, though some may need up to 200 bits of data per machine.

Some examples of relevant data for both the MSA FieldServer and the machines and components it connects to include:

- Temperatures

- Pressures

- Firmware updates

- Serial port connections and disconnections

- Errors

- Online/offline

When it comes to visual data, it’s important to understand that starts with a notification from the connected device. The data then gives the decision maker all the information they need to quickly analyze, troubleshoot, diagnose, and prevent or fix issues.

No longer does a boiler manager have to dispatch a worker to check gauges and then wait for the person to come back and report. All the relevant data is available in one place at one time in near real time.

So, what happens when components are added, systems are changed, or some new data point is needed? Well, with MSA FieldServer, it’s a seamless adaptation. The profile is already built, so the addition of a new machine just means that the required data points are brought through and visualized. Again, this means the user gets relevant data automatically (based on the profile) as it becomes available.

MAKING THE MOST OF DATA VISUALIZATION

When it comes to great data visualization, the key is to determine which data points are most necessary. Remember that there are literally hundreds of datasets be machine, so while it’s tempting to ask “everything” the better option is to ask for the most important data. Ask yourself:

- What data do I really need to see?

- How often do I need it to see this particular data?

- Are there any tolerances, limits, or parameters that will make the data more useful?

Again, the goal of data visualization is to help you do the job of keeping machines and systems up and running efficiently and effectively. For example, if you’re in charge of a data system and there are HVAC problems, you’ll want notifications and visual data so you can monitor when things are getting too warm, about to switch off, or in danger of a catastrophic crash.

Data visualization takes the guesswork out of decision making. It gives you what you need to know so you can intervene with preventive maintenance, whether that’s upping pressures, adding fans, or sending service trucks to the location.

SECURITY & EASY CONNECTION

Remember, all data visualization is not equal.

Relevant, visually driven data will provide you with trusted insight and repeatable metrics. MSA FieldServer not only does that, but it is also easy to configurate, as well as quick and simple to use.

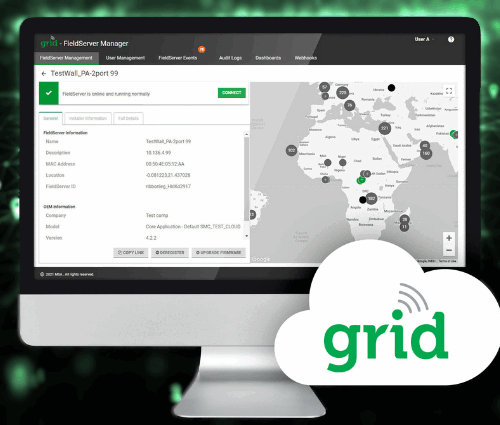

MSA FieldServer allows for data to be moved from a device to a local web server and to the cloud. The local web server is embedded in the FieldServer for local visibility so that means all you need to do is connect your laptop to the machine to view the data.

With MSA FieldServer, the cloud-based data is visualized by a dashboard, pulled via .csv or JSON format or sent to a third-party application via standard connectors. That means you and any other key stakeholders can see the data anytime, anywhere, from locations in the U.S. Germany, or China.

Further, because MSA FieldServer is based on Amazon Web Services (AMS), we’re able to provide a clear visual hierarchy along with reliable – and scalable – connectivity that makes your work easier, faster, and more effective.

If you want to learn more about how MSA FieldServer provides data that’s relevant, timely, and accessible, contact us via the form below.

And don’t forget to check back for our fifth and final post in this series on VPN. If you missed all or part of the series, you still have time to catch up:

References:

-

MIT News, In the blink of an eye, https://news.mit.edu/2014/in-the-blink-of-an-eye-0116

-

Wharton Magazine, Making data visualization more accessible, https://magazine.wharton.upenn.edu/digital/making-data-visualization-more-accessible/