The year 2022 is winding down and along with it comes an avalanche of new product introductions, like Rockwell Automation’s GuardLink 2.0 with new EtherNet/IP interface. As the number one Ethernet Industrial Automation protocol in the world in terms of nodes shipped, it’s not surprising that the number of shipped nodes will continue to increase exponentially—especially in light of the predicted growth of industrial communication. In fact, a recent forecast report from ResearchAndMarkets.com says the industrial communication market will grow to $141.04 billion by the end of 2023.1

The opportunities for how EtherNet/IP can continue to expand and enhance industrial automation is great. With opportunities, however, come challenges. Among those challenges is finding a way to reliably connect devices, controllers, sensors, instruments, and systems within the same network.

That’s where the EtherNet/IP protocol can make a difference. Although EtherNet/IP is one of many well-known protocols it is, perhaps, the most ideal for manufacturing and process automation applications.

Here are just a few of the many advantages the EtherNet/IP protocol delivers:

- Enables seamless control, configuration, and data collection from smart devices over a single network

- Is compatible with standard internet protocols, such as HTTP and FTP, as well as OPC UA

- Allows for higher speeds and more data transfer in less time

- Is a certifiable standard

The FieldServer EtherNet/IP Driver

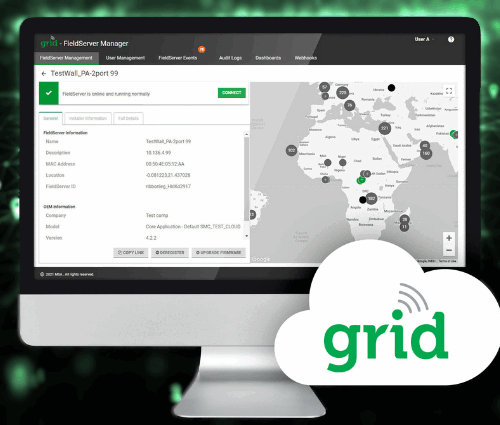

Our FieldServer gateway solutions include the EtherNet/IP driver, enabling seamless connectivity, as well as swift and secure transfer of data to and from devices.

For example, one of the largest global data centers in the world, Equinix, uses FieldServer gateways to connect Rockwell Drives (EtherNet/IP) to their Building Management System (BACnet/IP) in order to control the fan speed for the HVAC system. This allows for optimization of temperatures within the data center to ensure adequate cooling while also conserving energy in what is traditionally considered an energy-intense environment.

This level of automation is only made possible because FieldServer with EtherNet/IP enables Equinix’s different systems and disparate devices to talk the same language.

What does EtherNet/IP have to do with ODVA certification?

The developmental roots of EtherNet/IP date back to the 1990s and a standards development group known as ControlNet International, Ltd.2 This group later teamed up with the Open DeviceNet Vendors Association (ODVA) and, together in 2001, they introduced EtherNet/IP to the world.

ODVA has since taken over management of the technology. As part of their ongoing commitment to advancing open, interoperable communication in industrial automation for Industry 4.0, ODVA offers conformance testing for vendors who build interoperable products—like MSA FieldServer.

Why does ODVA certification matter?

The only way to achieve true interoperability is to have disparate devices from a wide variety of manufacturers work together, both seamlessly and reliably. ODVA specifications are intended to help accomplish just that. These specifications are designed to help ensure that there is a common network interface for products, regardless of who the manufacturer is.

Here’s what ODVA has to say about why they employ such a rigorous testing methodology:

By subjecting all products to this requirement, industry has vendor-independent assurance that products using ODVA technologies comply with ODVA’s specifications and can interoperate in systems with products from multiple vendors. The result benefits users by providing them with more freedom to choose vendors and products that are the best fit for the application requirements.

As we said at the beginning of this article, the future of industrial automation is big and getting bigger. To stay competitive, industrial organizations are going to need all their disparate devices to work together. Fortunately, ODVA-certified products can help make it happen.

FieldServer Achieves ODVA Certification

That’s why we’re proud to announce that FieldServer passed the test, and our name has been added to ODVA’s list of conformant products.

We should mention that ODVA’s conformance testing process is objective, independent, and thorough, which means that FieldServer’s compliance with ODVA’s EtherNet/IP standards is verified and confirmed without bias.

Even more exciting is that, unlike many products, FieldServer achieved compliance on its first attempt.

Choosing an ODVA certified EtherNet/IP gateway like FieldServer can give you peace of mind as you move closer to Industry 4.0. If you’d like to know more about EtherNet/IP gateways or interoperability among a multi-vendor system, we can help. Contact us to schedule a call.