Author: Jim Ralston – Business Development Manager, FieldServer

The data center market is on a growth trajectory that few industries can match, with an expected growth rate of more than $240 billion by 2030. According to McKinsey & Company, global demand for data center capacity could more than triple in that same period.1

The reason? Cloud computing, artificial intelligence (AI), and data storage demand. McKinsey estimates that the rapid construction of larger, more advanced, power-hungry facilities will bring about rapid change not only to the power infrastructure but also to the design of mechanical and electrical systems.1

That translates to massive opportunities for original equipment manufacturers (OEMs) to provide the systems and devices that power, cool, and monitor these mission-critical environments.

Of course, competition will be high and end-user expectations will be even higher, with data center operators demanding tighter integration, faster commissioning, and IT compliance from the outset.

And that’s where many OEMs could hit the proverbial wall—not because their products don’t work, but because they’re unable to connect with complex and disparate systems seamlessly.

Why Integration Is the New Normal

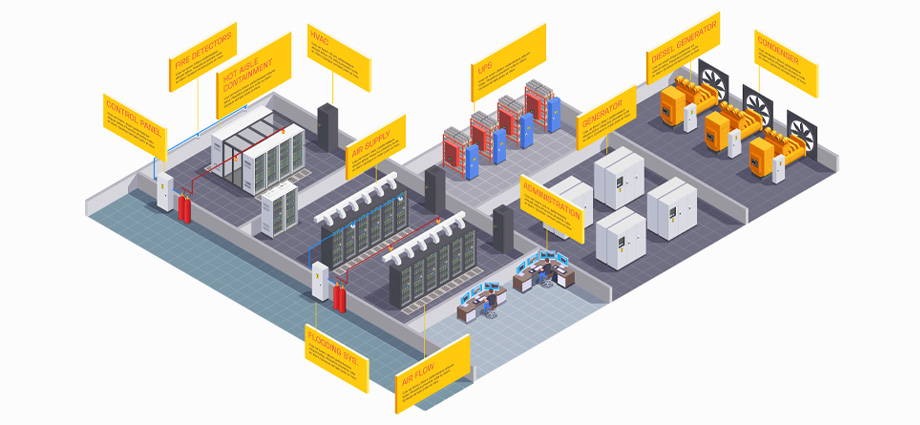

Data centers are comprised of layers of interconnected infrastructure, such as:

- Building Management Systems (BMS) that speaks BACnet

- Chillers and air handling systems using Modbus RTU

- Power meters that use Modbus or DNP

- Backup generators that rely on Modbus TCP

- Facility Safety Systems and Sensors using Modbus or fire alarm panel protocols

- Data Center Infrastructure Management (DCIM) systems that use SNMP

- IT networks that require subnet isolation and employ rigorous IP assignment policies

As data centers continue to grow in both capacity and complexity, so, too, will the need for seamless communication within the infrastructure (BMS, power systems, IT networks, HVAC equipment).

This post explores how OEMs can solve the interoperability puzzle with a multi-protocol gateway, which supports everything from BACnet to SNMP, all in a single device. Keep reading to learn how the right gateway simplifies integration, shortens commissioning time, and gives OEMs a competitive edge in a growing industry.

Does Your Hardware Speak the Language Data Centers Need?

For OEMs whose products are unable to communicate across all those layers and/or comply with stringent IT policies, they’ll likely be left behind, with their products never making it into a lucrative data center project.

In today’s data center environments, integration isn’t just a feature—it’s a requirement. OEM systems should be able to interface with a range of platforms, from facility-level BMS to enterprise-grade DCIM to SCADA systems. The challenge, however, is that each of those systems could be using a different protocol.

If an OEM’s product can’t speak the language, it doesn’t matter how reliable or advanced it is—it becomes a liability.

That’s where a smarter way to connect comes in: a multi-protocol gateway, like MSA’s FieldServer gateways.

Protocol Support for 140+ Languages

Our gateway solutions are a universal translator, facilitating seamless communication between OEM devices and the data center’s broader infrastructure ecosystem. No custom integration required. No costly long-term development costs.

That’s because FieldServer gateways support 140+ protocols, including the following protocols, which are commonly used in mission-critical data center environments:

- Modbus RTU & TCP: Still one of the most widely used protocols in industrial and power systems, Modbus enables straightforward data sharing from meters, chillers, and backup generators. FieldServer gateways bridge these legacy or serial devices to modern networks without costly redesigns.

- BACnet/IP & MS/TP: The go-to standard for BMS, BACnet ensures smooth integration between HVAC or environmental controls and facility operations. For maximum flexibility, FieldServer gateways handle both IP and serial versions.

- SNMP: Essential for IT tools and DCIM platforms, SNMP allows OEM equipment to feed performance data, fault notifications, and usage metrics into monitoring software. With FieldServer gateways, an OEM product becomes “visible” to the systems that manage uptime and capacity planning.

- EtherNet/IP: Common in industrial automation environments, EtherNet/IP enables OEMs in the power and control space to connect to PLC-based systems. Our gateways make it easy to bridge HVAC, energy, or mechanical equipment with enterprise-wide control logic.

- DNP3: A key protocol in utility and energy monitoring applications, DNP3 supports robust, time-stamped data transfer over SCADA systems. For OEMs building power or energy-related products, FieldServer gateways help ensure compatibility with utility-level infrastructure.

By consolidating protocol translation into a single, compact device, FieldServer eliminates the need for multiple converters. Plus, it reduces supply chain complexity and simplifies installation—without compromising performance or flexibility.

From chillers to power monitoring systems to fuel tank sensors, a multi-protocol gateway helps OEMs ensure that their products can integrate seamlessly into (and meet the demands of) a wide range of customer environments.

The Protocol Gateway Designed for Data Center Demands

FieldServer gateways are engineered to meet real-world demands that OEMs face when deploying products in data center environments. From first installation to final approval, they can help ensure that OEM equipment integrates cleanly, communicates reliably, and passes IT scrutiny without extra engineering effort or expertise.

Here’s a look at some of the features that enable OEMs to deliver fast installs, seamless integration, and secure, compliant products:

- Dual Ethernet ports allow for network segmentation. This means an OEM device can operate independently on one subnet while reporting into a BMS or DCIM system on another. The systems stay securely isolated yet accessible, without the need for custom network configurations.

- Support for both DHCP and static IPs enables OEM products to conform to the site’s existing IP assignment policies. This is true whether IT manages addresses dynamically or requires manual allocation. No code changes or special firmware are needed.

- Custom device profiles enable consistent, repeatable configurations. OEM equipment can be shipped FieldServer-ready for faster installation and reduced manual setup in the field.

- Remote access can be toggled off, speeding up security reviews and giving OEM customers peace of mind.

- No open OS and locked IP ports reduce the attack surface of the OEM solution. There are no surprise updates, no unnecessary access points, and no need for the OEM team to manage operating system patches.

Built-In Market Readiness

Data centers are high-barrier, high-expectation environments. For an OEM product to make it into consideration or a data center spec, it must be both reliable and ready to deliver what the site demands—seamless integration, protocol support, and compliance with IT standards.

FieldServer helps OEMs meet those demands with these built-in advantages:

- Pre-validated interoperability

- Enterprise-ready networking

- Hardened cybersecurity features backed by third-party penetration testing

- Security measures aligned with ISO/IEC 27001

Bottom line: FieldServer gateways don’t just make OEM equipment work in a data center. They help it belong there.

OEM Takeaways: What to Look for in a Gateway Integration Partner

FieldServer gateways are already embedded in thousands of OEM solutions across the data center ecosystem, from power meters and cooling systems to fuel monitoring and backup power. For OEMs evaluating a gateway partner, here are the capabilities to look for to make integration easier, deployment faster, and long-term support more scalable.

- Seamless, out-of-the-box connectivity with access to 140+ supported protocols, including Modbus, BACnet, DNP3, SNMP, EtherNet/IP

- Dual Ethernet ports to isolate operational and management traffic without extra hardware

- Custom device profiles to help reduce engineering needs and speed up commissioning time

- Sophisticated built-in diagnostics to quickly resolve configuration and network problems

- FieldSafe cybersecurity for built-in protection with no open OS and restricted IP ports

- Ongoing third-party penetration testing to ensure highest security levels

- DHCP + static IP support for connectivity in any network environment

- Proven in critical data center systems, including chillers, power meters, flow meters, air handlers, fuel monitors, backup power

- Easy integration with leading DCIM platforms via SNMP and BACnet/IP, making OEM devices instantly compatible with the tools data centers already use

Final Thoughts

Data centers are becoming increasingly complex, and OEMs that can deliver on connectivity, compliance, and control are the ones who will stand out.

Ready to develop smarter, spec-ready products for data centers? Contact us to learn how FieldServer gateways can integrate into your next product release.

Reference:

Jain, A., & Shah, A. (2024, April 4). AI power: Expanding data center capacity to meet growing demand. McKinsey & Company. https://www.mckinsey.com/industries/technology-media-and-telecommunications/our-insights/ai-power-expanding-data-center-capacity-to-meet-growing-demand